K- 34, MIDC Ambad, Near Symbiosis College, Behind Hotel Gateway, Nashik - 422 010.

- Call Us : (+91)-98817 45040, (0253)-2383323

- Mail Us : info@shanmukha.com

Metallurgical Failure Analysis Case Studies

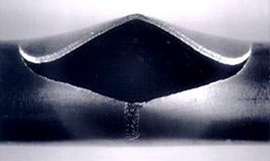

Failure analysis is performed by systematically examining, testing and analyzing the failure, starting with gathering information about the component, its application and history, followed by a detailed visual examination, then nondestructive testing (magnetic particle test, dye penetrant test, low magnification stereoscope, etc.), leading to high magnification examination and destructive testing (such as: scanning electron microscopy (SEM), sectioning the sample for Metallographic micro analysis, Hardness testing, Chemical Analysis, Mechanical testing, etc.).

All evidence and forensic failure analysis results are photographically documented and presented in a report, which interprets and explains each finding in a clear and concise format. We also provide: reports of evidence in support of resolving insurance claims, expert witness testimony, and litigation support in product liability and accident cases.

A typical forensic metallurgical failure analysis includes the following eight steps :

- Collect failed component background information and service history.

- Perform a visual examination of failed and related components in the as-failed condition. Perform low magnification examinations using a stereomicroscope to locate critical areas for further analyses or testing. Take dimensional measurements as necessary.

- Analyze the fracture or degraded surfaces utilizing a Scanning Electron Microscope (SEM) at high magnification.

- Using the SEM, determine the failure mode and origin/initiation site. Investigate the initiation site for unusual conditions or contributing factors. Identify and characterize the failure mechanism (fatigue, embrittlement, overload, type of corrosion, etc.) Investigate for unusual stress risers.

- Select, prepare, examine and analyze the cross-section microstructure in the region of failure/fracture initiation. Analyze conditions of manufacturing reflected in microstructure and investigate potential flawed conditions. Investigate material quality and heat treat conditions.

- Perform a chemical composition analysis of the failed component (alloy and impurities), and coatings or platings.

- Perform mechanical and other testing (hardness, strength, toughness, etc.)

- Analyze all gathered evidence and test results to formulate an engineering opinion and conclusion.